Marine grade aluminum checker plate has stricter processes and better anti corrosion performance standards compared with ordinary aluminum checker plates.

Haomei Aluminum can produce marine aluminum checker plates with different styles and different surface treatments according to the needs of customers. The CSS, DNV, LR, ABS, BV certification can be provide if you need.

Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other | Al | |

Single | Total | ||||||||||

5052 | 0.25 | 0.40 | 0.10 | 0.10 | 2.2-2.8 | 0.15-0.35 | 0.10 | -- | 0.05 | 0.15 | Remainder |

5754 | 0.40 | 0.40 | 0.10 | 0.50 | 2.6-3.6 | 0.30 | 0.20 | 0.15 | 0.05 | 0.15 | Remainder |

6061 | 0.4-0.8 | 0.7 | 0.15-0.40 | 0.15 | 0.8-1.2 | 0.04-0.35 | 0.25 | 0.15 | 0.05 | 0.15 | Remainder |

6063 | 0.20-0.6 | 0.35 | 0.10 | 0.10 | 0.45-0.9 | 0.10 | 0.10 | 0.1 | 0.05 | 0.15 | Remainder |

Alloy | Temper | Thickness(mm) | Width(mm) | Length(mm) | Surface | Standards | Patterns |

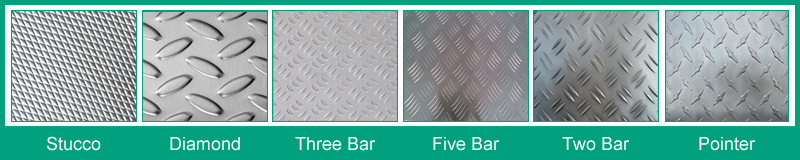

5052 | F, O, H12, H14, H16, H18, H19, H22, H24, H26, H28, H32, H34, H36, H38, H111, H112, H114 | 0.15-600 | 20-2650 | 500-16000 | Bright Finish/Mill Finish | ASTM-B209. EN573-1, GB/T3880.1-2006 | Diamond, Propeller, 1 Bar, 2 Bars, 3 Bars, 5 Bars |

5083 | O, H12, H14, H16, H18, H19, H22, H24, H26, H28, H32, H34, H36, H38, H111, H112, H114, H116, H321 | 0.15-600 | 20-2600 | 500-16000 | |||

5086 | O, H111, H112, H116, H321 | 10-50 | ≦3600 | Under 6000 | |||

6061 | F, O, T6, T651 | 0.8-10 | 100-1220 | Under 6000 |

5000 and 6000 series marine grade aluminum tread plate has high strength, is particularly resistant to salt water corrosion, it is easy to form, stamp and weld. Applied to boat hulls,superstructures, gangways, ramps, shipping drums,support structures for marine applications.

1, Excellent corrosion resistance.

Since ships are used in harsh seawater media and marine environments all year round, corrosion resistance is one of the main signs of marine grade aluminum tread plates.

2, High specific strength and specific modulus.

The structural strength and size of a ship are closely related to the yield strength and elastic modulus of the material. It is usually difficult for high-strength aluminum alloys to have excellent corrosion resistance and weldability at the same time. 5xxx aluminum checker plate is often used.

3, Good cold and hot forming properties.

Because the shipbuilding has to undergo multiple treatments such as cold processing and hot processing, the marine aluminum alloy must be easy to process and form, and still meet the requirements of strength and corrosion resistance after processing.

4. Excellent welding performance.

At present, the automatic argon arc welding method is mainly used in ships. Good weldability means that the tendency of cracks formed during welding of aluminum alloys is small. 5XXX aluminum diamond plates have good welding crack resistance.

1) very high quality with the third party inspection: SGS, BV, CE,COC, AL and other

2) good price with flexible payment:TT, L/C etc.

3) short lead time and on time delivery

4) free samples and freight charges in your side

5) professional service

6) quality guarantee after receiving the goods: money return for the bad goods or deliver new goods if any problems happen.