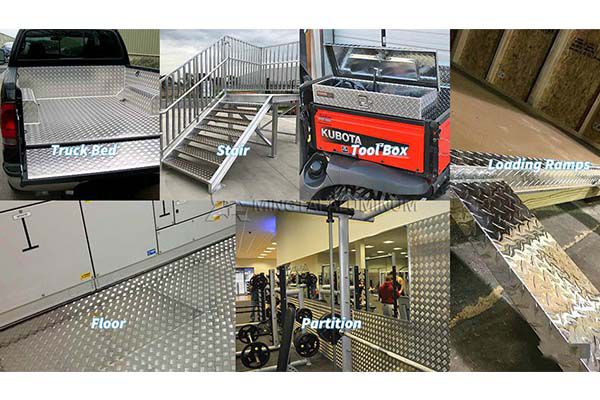

The durbar plate has many advantages such as beautiful appearance, anti-skid and strengthening performance. Durbar flooring is widely used in floor plate of transportation, construction, decoration, equipment, machinery, shipbuilding and other fields.

Grade | 1050, 1060, 1100, 3003,5052, 5083, 5086, 6061 etc. |

Temper | O, H12, H14, H16, H18, H24, H24, H26, H32, H34 |

Standard | ASTM-B209. EN573-1, GB/T3880.1-2006 |

Thickness | 0.8 - 12mm |

Width | 400-1220mm |

Length | max 6000mm for sheet or as required for coil |

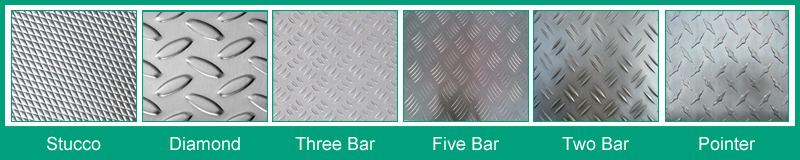

Pattern | big 5 bar / small 5 bar / 3 bar / diamond / pointer |

Surface treatment | polished, mill finished, power coated, sand blast, anodized, brushed. |

Surface Protection | Oleo phobic coating, protective film, paint coating. |

Packing | Export wooden pallets. The bundle weight not exceed 2MT. Loading:by 1x20GP. |

1, Accurate size, good anti-slip effect,wide range of applications.

2, Strong plasticity, easy forming and excellent processing performance.

3, XXX can form a dense and strong oxide film on aluminum surface to prevent the intrusion of oxygen, so it has good corrosion resistance.

4, Good elongation and tensile strength, fully able to meet the normal processing requirements (stamping, stretching), high formability.