5 Bar Aluminum Tread Plate Factory Production Process

Dec-05-2024

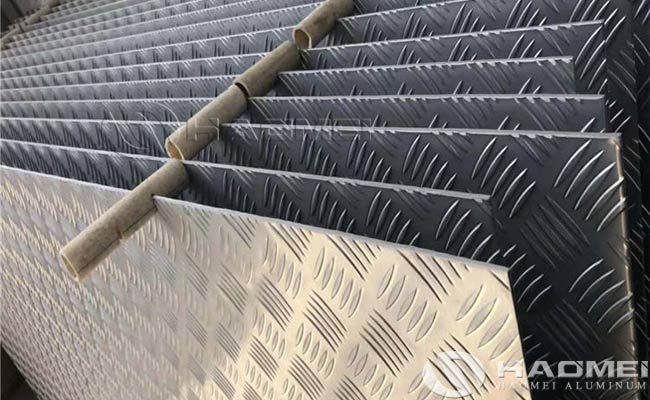

5 bar aluminum tread plate is a kind of aluminum alloy plate with five longitudinal bars on the surface, usually used in the application scenarios that need anti-slip, wear-resistant and certain load-bearing capacity. 5 bar aluminum tread plate factory is usually made of 1000, 3000, 5000, 6000 series aluminum alloy material. Due to the ribbed surface design, it can effectively enhance the friction and provide good anti-slip effect, which is suitable for use on floors and platforms where anti-slip is required.

Product details produced by 5 bar aluminum tread plate factory are:

- Material: High quality aluminum alloy (such as 3003, 5052, 5083, 6061)

- Specification: Customized according to customer's requirement, common thickness ranges from 1mm to 8mm; width and length depend on the actual application.

- Pattern type: 5-bar design, providing good anti-slip effect, especially suitable for slippery environment.

- Wide range of uses: can be used in building decoration (e.g. flooring, stair treads), industrial platforms, vehicle flooring, ship decks, etc.

The production process of 5 bar aluminum tread plate factory can be roughly divided into the following steps:

1. Preparation of raw materials

First of all, select the aluminum alloy raw materials suitable for making the pattern plate. For 5-bar aluminum tread plate, aluminum alloys with good mechanical properties and corrosion resistance, such as 5083 or 6061 and other series, are usually selected. These aluminum alloys contain elements such as magnesium and silicon, which can provide sufficient strength and toughness.

2. Hot or cold roll forming

After heating the prepared aluminum alloy ingot to the appropriate temperature, it is either passed through a hot rolling mill for initial forming, or a cold rolling process is used directly to form flat sheets. The purpose of this step is to obtain the required thickness and flatness for subsequent processing.

3. Pattern pressing

This is a key step in the production of aluminum tread plates. By means of a special embossing mold, high pressure is applied to the surface of the plate to form a specific pattern design on the surface of the aluminum plate, such as a 5-bar design. This process can be done in a hot state (hot pressing) or in a cold state (cold pressing). Hot pressing is used for thicker plates, while cold pressing is more commonly used for thinner plates.

4. Cutting and trimming

Tread plates are cut accurately according to customer requirements or standard dimensions using shears or other cutting equipment to ensure that they are of the required length and width. In addition, the edges are sanded to remove burrs and ensure the quality of the product's appearance.

5. Surface treatment

In order to enhance the aesthetics and durability of the 5 bar aluminum tread plate, a series of surface treatments are applied at the end of the process, including but not limited to:

Anodizing: to enhance abrasion resistance and corrosion resistance.

Powder Coating or Paint Finish: increases color options and provides an additional layer of protection.

Polishing: improves gloss and provides a smoother surface.

Characterization of the produced 5 bar aluminum tread plate are:

- High strength and light weight

- Excellent corrosion resistance

- Easy to maintain and clean

- Variety of finish options to meet different aesthetic needs

Please note that specific manufacturing processes and product parameters may vary depending on the technical level of different 5 bar aluminum tread plate factories and market demands. If you have specific needs or questions, we recommend contacting the manufacturer directly for more detailed information.